3D Printing

I recently made the purchase of a 3D printer, and it has been running almost nonstop.

Below are my own designs using Fusion 360. Understanding how to model to optimize for 3d printing has been a learning curve.

Use the link at the bottom of my page to follow along as I post my models on printables.

Copy Carver Work Bench

Currently in process.

I designed and am making a copy carver, a tool that utilized a router and sylis on a gantry to duplicate an object by carving the copy out of wood.

Main benefit is cost, it is significantly cheaper that a CNC router table. I plan to utilize the 3D printer in order to make a master and then copy that into wood.

Tacoma Camping Drawers

Out of the need for a home base while we are out camping came this bed platform. Also useful on the days when we leave for the weekend afterwork on a Friday and are too tired when we get to the trailhead to set up a tent.

Rather than spend hundreds on heavy duty drawer slides, I make my own with square tubing and skateboard bearings. One draw is set up as our kitchen and the other or storage with dividers.

1923 Canoe

Combining my love for woodwork with my passion for the outdoors and canoeing I took on the lengthy project of restoring a wood canvas canoe.

I met my partner as a canoe guide, so it only seemed fitting that we needed our own.

Here I am starting the process of removing the parts that I will eventually replace. I have more to take off before I can start to rebuild

I have pulled off the planking on the sides to expose the tips of the ribs. I was able to repair the tips of each rib where there was severe rot by scarfing in a new piece of wood.

Gerstner style too chest

What wood worker would I be if i did not have a place to store some of my tools? I based my design off of a company called Gerstner and sons that have been around for a while and make machinist style tool boxes out of wood. I was even able to source most of my hardware from them.

After getting into wood working, I wanted to take on a major project to highlight and hone my skills with hand tools. I am a really big fan of joinery, interlocking wood without the use of hardware such as screws. I based this design after a Gerstner and Sons machinists tool box.

I used the difference in the heart and sap wood on the side panels to highlight the dovetails.

Deskbuddy

A project from my last semester of my undergrad. The course was split into two semesters and I ended up having to do it backwards to participate. The focus of this semester was to design something that was school themed and used multiple manufacturing processes.

Thus, the Deskbuddy was born. A waterjet cork board inset in the R, a clock inset in the P and a die cut magnet I inset in the I. all assembled and ultrasonicly welded onto a deep drawn aluminum base with grooves for pens. The letters were also made in two halves and ultrasonicly welded together and were injection molded.

I modeled all the letters to be plastic injection molded and then welded together.

this is the prototype made using 3d printing. testing out the unique features we have on each letter

Shaper Origin Projects

One of my more recent tools is a Shaper Origin, a hand held CNC router. This eliminates the need for a gantry table and makes the work space infinite. I am just scratching the surface of what I can use it for.

Fusion 360 has a build in tool for the Shaper Origin, allowing for easy export. I still make the whole model and then parse it out so that I can maximize material use when using the router.

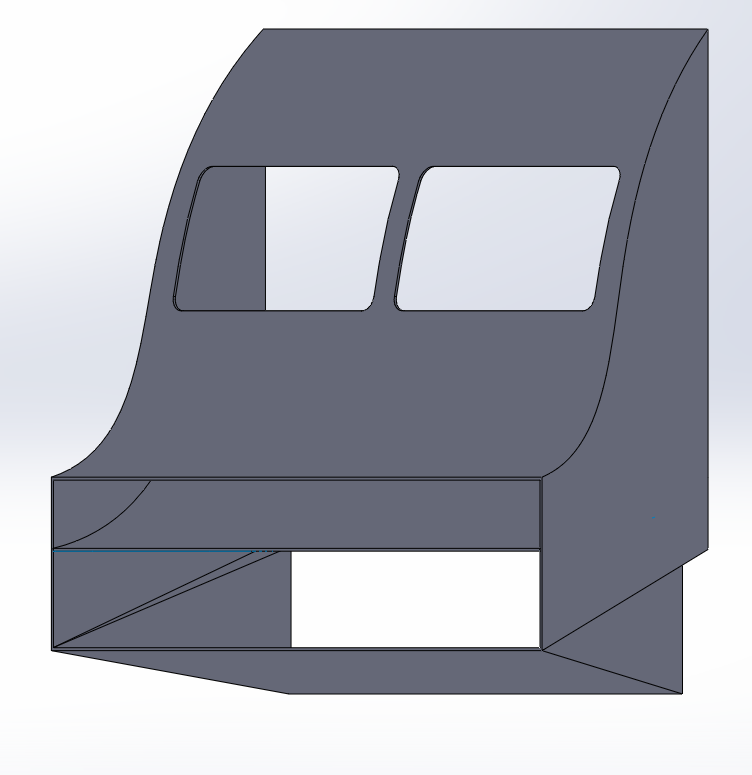

BMW M3 Intake Vent

A friend came to me with an idea for his race car. He wanted to increase down force on the from end, and maintain cooling temperatures. There are two main intakes on the BMW M3, it has the “Kidneys”, the two semi oval shaped cut outs, and then a rectangular cutout below that on the front end. We wanted to shut off air flow through the kidneys and only have air come in through the bottom rectangle. He had tried this before and was unsuccessful resulting in overheating. I was able to model the vent in Solidworks, and did a flow simulation after adding in vanes, everything looked good. I used my Shaper Origin CNC router to cut out the panels and rivet it together.

After some iterations, we are on V4 ( pictured lower). We reduced the internal vanes from two to one. Added an optional slide in cover for the kidneys on the off chance that the main intake gets covered. For the car set up, there is a oil cooler mounted below the radiator, this is where the folds in the sides come in. Also wanting to reduce rivets, I combined the sides with the bottom. Next project is probably an bending break.

Puckman

School Project from RPI. This was part of the advanced manufacturing lab that was a two semester course I did in reverse. I joined this project after the main design was completed in the prior semester. The second semester takes the project into mass production. We had to make an assembly line, manufacture all the parts, then produce and package 400 units.

This project included a deep drawn hat, ultrasonicly welded onto a plastic injection molded hokey puck. The body was made in three pieces press fit together with a waterjet hokey stick overmolded into the hand. He is press-fit into the base and then a vacuum molded dome is snap fit over. topped off with a music box in the base that plays the school fight song.

CNC Plasma Table

After talking a friend into purchasing a CNC plasma table, we have had fun modeling, CAM-ing and cutting parts ranging from simple bottle openers, brackets to use under the hood of a car, and metal signs.